The Technology Leader In Dry Film Resist Materials

Innovative Dry Film Resist Materials

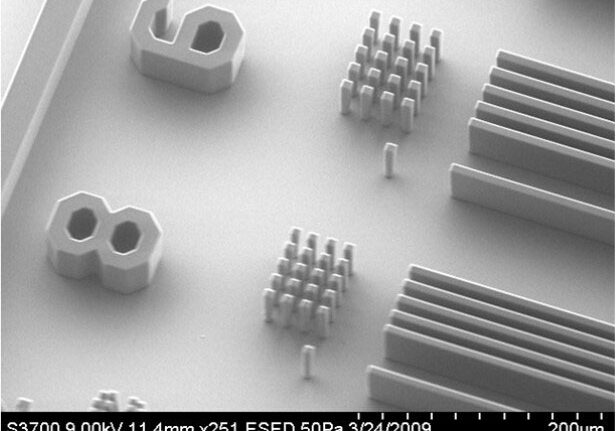

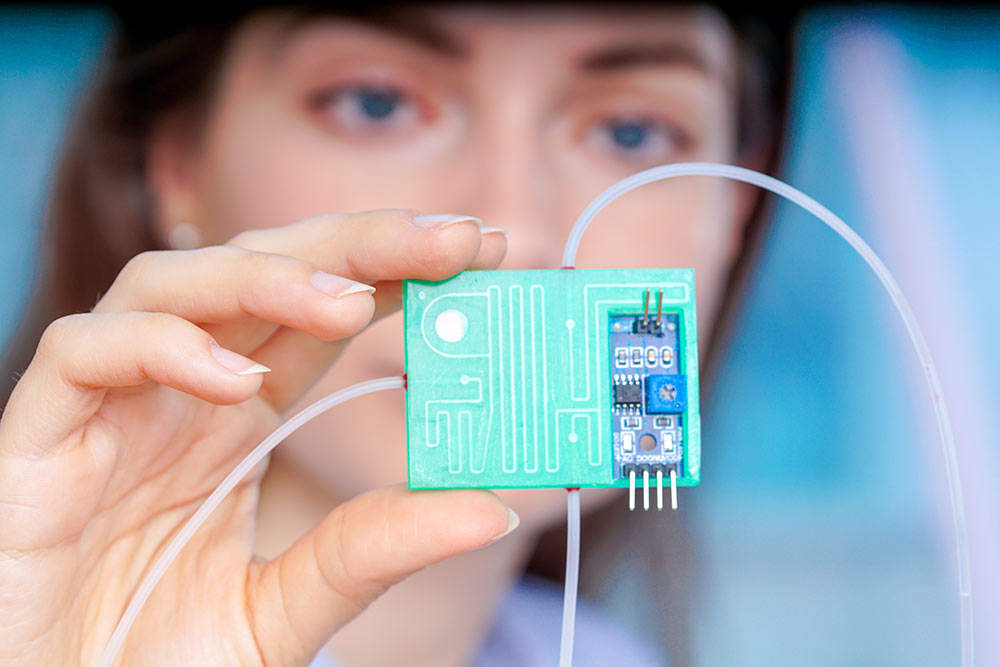

Consumer electronics, biomedical and other products based on micro-structures are everywhere and life without them is unimaginable. Many of these every day electronics products from mobile phones and computing devices to “smart” watches to entertainment systems, toys and accessories involve intricate manufacturing processes that include hundreds of individual steps. Today successful production requires device and semiconductor manufacturers to abandon outdated approaches and technologies and use advanced imaging materials and sophisticated processes.

DJ MicroLaminates delivers advanced materials that are needed to enable the success of device manufacturers. By offering high resolution imaging with critical adhesion and photoimaging capabilities, our products provide a vital link between the visionary designs for the latest electronic devices and the companies that produce them.

Product lines of

SUEX® and ADEX™

Applications of Dry Film Sheets

Have your questions answered

Innovative Leaders

DJ MicroLaminates' Product Line Consists Of SUEX® And ADEX™

We offer a range of shapes, sizes and thicknesses including:

- SUEX® Thick Dry Film Sheets – thicknesses of 100µm (microns) and greater

- SUEX® Thin Dry Film Sheets – thicknesses of 20, 30, 40, 50 and 75µm

- ADEX™ Thin Dry Film Sheets & Rolls – thicknesses from 5 to 75µm

- Custom pre-cut sheets or rolls

Epoxy Based Resists That Exhibit Excellent Chemical Resistance

Applications:

- Semiconductors and Interconnect

- Patterning and Packaging

- Consumer Devices

- Medical Devices

- Microfluidic Devices

DJ MicroLaminates Offers Versatile, Clean, Easy, And A Rapid Way Of Applying Film To Substrates

Our SUEX® and ADEX™ lines of epoxy photoresist are available in a thickness range of 20µm to more than 500µm

DJ MicroLaminates features Thin and Thick Dry Films That Are Antimony-Free and Virtually Waste-Free

SUEX® and ADEX™ have significant advantages for manufactures:

DJ MicroLaminates Partners

Stay Connected